3D Model to Predict the Moisture Diffusion Patterns Through Bionanocomposite Films

In food packaging applications, biopolymers are explored more due to the adverse effects of synthetic polymers on environment. However, one of the primary concerns of the bio-based polymers is their poor barrier properties. This can be regulated by the use of nanofillers/ reinforcements with at least one dimension of nanoscale size. Among other nanofillers like nanospheres (nanoparticles), nanotubes and nanorods, nanoplatelets are preferred in these applications for their single nano-sized dimension. Thus, the obtained bionanocomposite films improve barrier, thermal as well as mechanical properties of the films; whereas, the amount, orientation and type of filler added has influence on these properties.

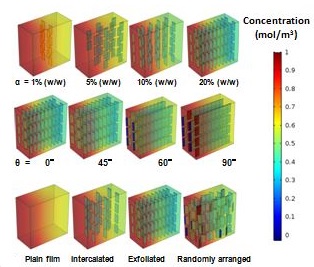

In the present study, a finite element 3-D model of bionanocomposite packaging film was developed and the moisture barrier property was analysed in terms of relative diffusivity. The effect of different volume fraction, aspect ratio, orientation angle and level of exfoliation of nanoplatelets on relative diffusivity were evaluated. It was observed that volume fraction showed inverse relation to diffusivity up to a threshold level. Also, orientation angle had direct relation to that of diffusivity. With increase in orientation angle, relative diffusivity was also found to increase. Further, exfoliation reduced the moisture diffusion. The validated model can be used to predict the moisture diffusion pattern into nanocomposite films and thereby aids in designing of nanocomposite films with moisture barrier properties.

Download

- bharathi s k_poster.pdf - 6.52MB

- bharathi s k_abstract.pdf - 0.1MB