Effects of Mold-Casting Contact on Solidification in Continuous Casting

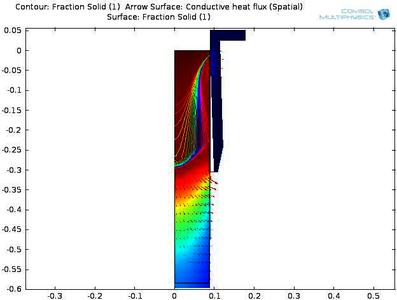

This communication describes a model created to investigate the effect of mold-metal contact on casting solidification in the continuous casting process. The Heat Transfer and Solid Mechanics modules of COMSOL Multiphysics® simulation software are used to construct a non-linear finite element model of the process. The model considers a typical continuous casting configuration consisting of a water-cooled sleeve mold into which molten metal is poured. Direct water-cooling is applied at the mold exit to further quench the solidifying slab. The model simulates the coupled thermal and phase change processes and thermo-mechanical phenomena in the system. Because of the large range of temperatures involved, temperature dependent property values are used for both thermal and mechanical properties. An attempt is made to represent the complex thermomechanical contact conditions existing at the mold-casting interface. The model predicts the temperature and displacement fields in the system operating under steady state conditions and suggests strategies for improved control and optimization of the process.