Finite Element Analysis of Electro Discharge Machining process

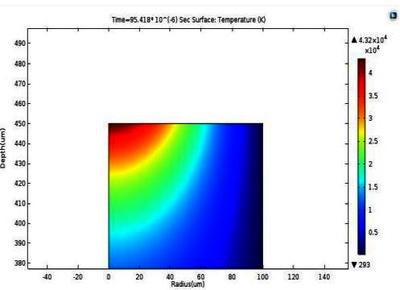

The present research work aims to present thermal analysis of Electrical Discharge machining. During its machining process a large amount of heat is generated due to sparking phenomena, It has been assumed that heat distribution follows the Gaussian Distribution function. As such a high amount of spark energy strikes with the Anodic zone, this zone starts melting & resulting surface get machined and thus formation of crater takes place on the top surface.

In this paper analysis has been performed using Finite Element software package "Heat Transfer Module " of COMSOL Mutiphysics®. The variables such as, Current, Voltage, Ton Time, Toff time, park radius, fraction of energy, material properties, Heat distribution function, are provided as input parameters with suitable boundary condition loads are applied to the entire material surface. After computing this simulation, dimensions of resulting crater depth and crater radius are obtained also in addition to this analysis Distribution of Temperature over the Entire workpiece surface is also predicted without investing money & time to perform Die Sinking Electro Discharge Machining process in our lab.

Download

- singh_poster.pdf - 0.25MB

- singh_paper.pdf - 0.36MB

- singh_abstract.pdf - 0.06MB