Iterative Caloric Effects Modelling Using COMSOL Multiphysics® and the LiveLink™ for MATLAB®

Scientists and engineers have been designing and developing computational tools for the numerical simulation of heat transfer processes involving non-conventional heating or cooling effects for several years. Caloric effects rely on temperature variations upon external stimuli, e.g. magnetic or electric fields, which induce variations on the thermal properties of the caloric material. The simplest way to mimic the caloric effect is by adding or subtracting a given quantity (the adiabatic temperature change) to the temperature of the caloric material during magnetic field application/removal periods.

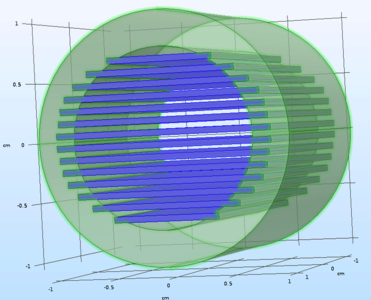

This paper presents a model of an Active Magnetic Regenerator (AMR) refrigeration cycle designed to simulate a magnetocaloric device. A two-dimensional model is built and the magnetocaloric effect is modelled. The flow of the heat transfer fluid is governed by the Navier-Stokes equations, and the thermal energy conservation equation governs the heat transfer and the enthalpy flow in the fluid, the heat transfer in the solid, and the solid-fluid heat transfer. These physics are coupled together by COMSOL Multiphysics® combining the Heat Transfer in Solids and the Laminar Flow interfaces. The Magnetocaloric Effect modeling is achieved by using the COMSOL Multiphysics® functions to interpolate the experimental data of adiabatic temperature change and specific heat (which are functions of temperature and magnetic field).

This is difficult to implement in COMSOL Multiphysics® since the temperature values cannot be manipulated while the simulation is running, and magnetization/demagnetization processes have to be divided in several Time Dependent Studies, turning the data extraction a tedious and time-consuming task. This sets the objective of finding an efficient methodology to perform systems’ design and data analysis within a reasonable time frame.

A thorough discussion on the methodology will be exposed through a combined application of COMSOL Multiphysics® with the LiveLink™ for MATLAB® to develop a new workspace, where the magnetocaloric effect can be controlled by manipulating the temperature matrix of the magnetocaloric domain. The source code of the conjugate heat transfer model generated in the format of a .m file is able to run in MATLAB® in order to investigate the temperature distribution in the magnetocaloric domain, eliminating the need to run a full simulation, from end to end, to validate the model’s solution. Furthermore, when establishing the system’s geometry, and by using the Form Assembly Geometry finalization, we can guarantee that the created mesh elements do not overlap the domain boundaries between liquid and solid. Delving more deeply in this methodology shows that, using the connection to COMSOL Multiphysics® Server, the simulation can be customized by loading the created system’s model through a mph file at the beginning of the code. Moreover, thanks to LiveLink™ for MATLAB functionality, the results are also easy to monitor and collect automatically.