Silicon Nitride Corrugated Membrane with High-Width-Aspect-Ratio for MEMS Microphones

Micro-Electro-Mechanical Devices such as acoustics sensors, finger print sensors, tunable capacitors etc. are widely used in commercial applications. The pressure sensors use membranes which deflect upon applied pressure load. The most important aspect of any pressure sensor is its membrane which is made of silicon material. In this paper, a corrugated silicon nitride membrane is studied which offers the possibility to control the sensitivity of thin membrane by optimizing the geometrical parameters. The acoustical sensitivity is defined as the change in center deflection of the membrane subjected to change in applied pressure and is measured in nm/Pa. The corrugated circular membrane has a greater advantage over the planar circular membrane as it significantly helps in reducing the initial stress of membrane in center region of interest and thereby improving membrane sensitivity.

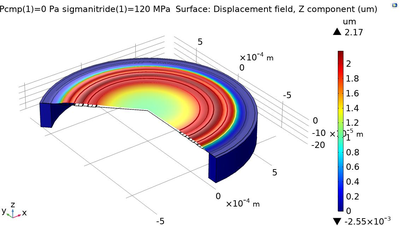

A trapezoidal shaped corrugated silicon nitride membrane with diameter 1.4mm and thickness 1.1um is studied with variations in corrugation widths and corrugation depths to optimize the acoustical sensitivity. The corrugation walls are inclined at 60 degrees to the bottom surface of the corrugation. The width and depth of corrugation is optimized with different levels of initial stresses ranging from 120 MPa to 220 MPa to obtain maximum acoustical compliance or sensitivity of the membrane. The High-Width-Aspect-Ratio corresponds to the dimension of corrugation width over thickness of membrane. This ratio is 85:1 and 50:1 for 2 and 3 corrugations respectively for obtaining maximum acoustical sensitivity.

A 2D axisymmetric model of the membrane is used in this study using COMSOL Multiphysics® software. The Structural Mechanics Module is selected for stationary analysis. The corrugation corners are very finely meshed to avoid any stress concentration which can affect the sensitivity of the membrane. The material properties are directly taken from in-built material library of COMSOL Multiphysics® software. The simulated 3D section of the model is shown in Figure 1. The obtained results indicates that, for a given corrugation height, as intrinsic stress of membrane is increased, the sensitivity of the membrane drops. The sensitivity shows an increasing trend with corrugation width. However, if width is further increased at a given intrinsic stress and given corrugation depth, the acoustical sensitivity reaches a maxima and then it shows a declining trend. This effect is seen at different widths for 1, 2 and 3 corrugations as shown in Figure 2. Our study also gives an indication that acoustical sensitivity need not increase always with number of corrugations and with increase in width, and therefore there is always a scope to optimize geometry to gain maximum sensitivity. This study opens a broader range of option for sensitivity optimization for the corrugated membranes that can further boost the sensing or acoustic signal.