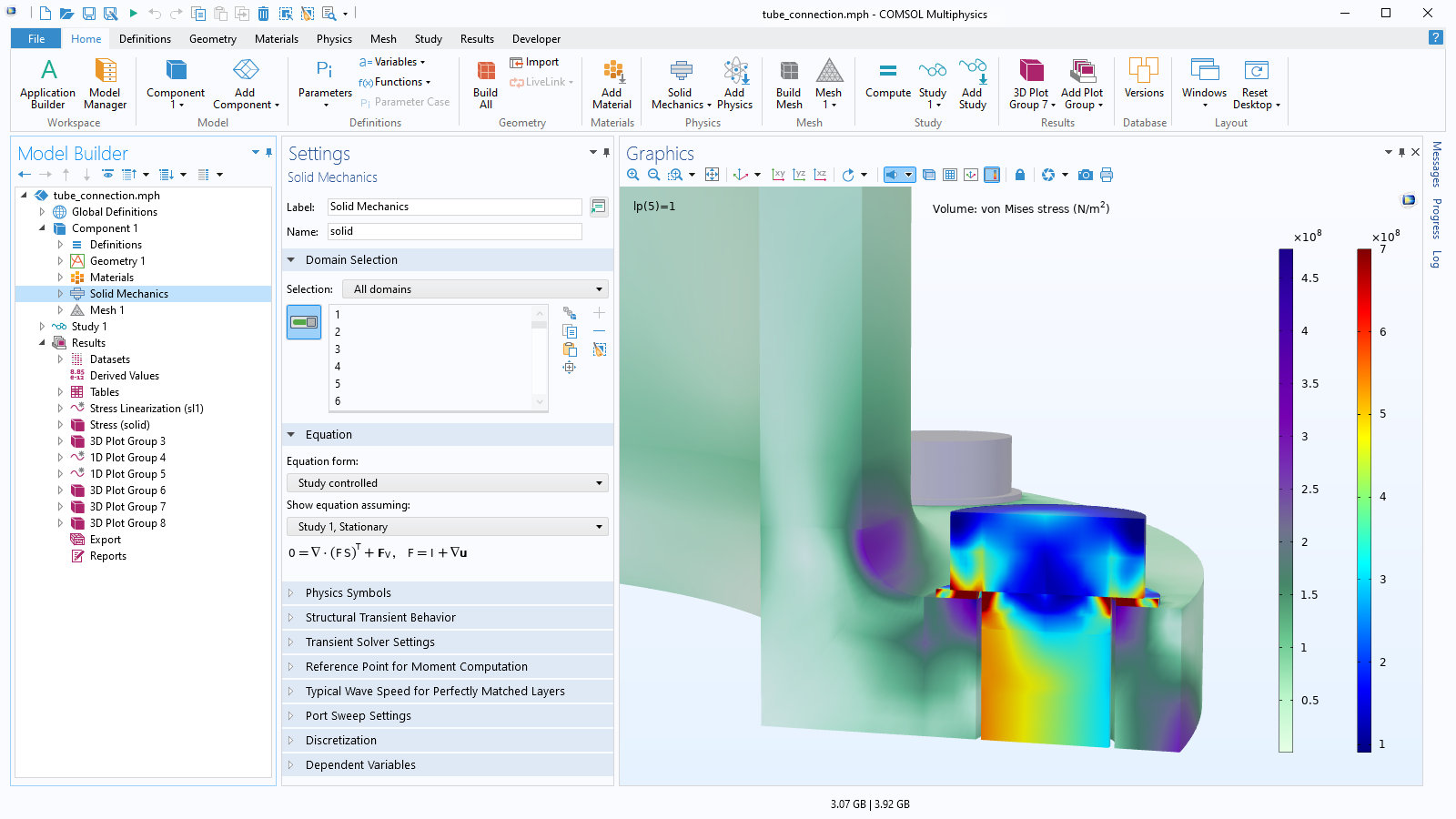

Multiphysics Modeling Provides Accurate Results

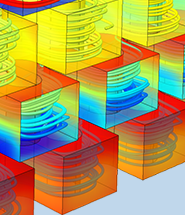

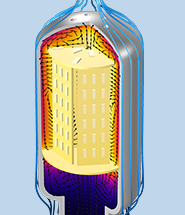

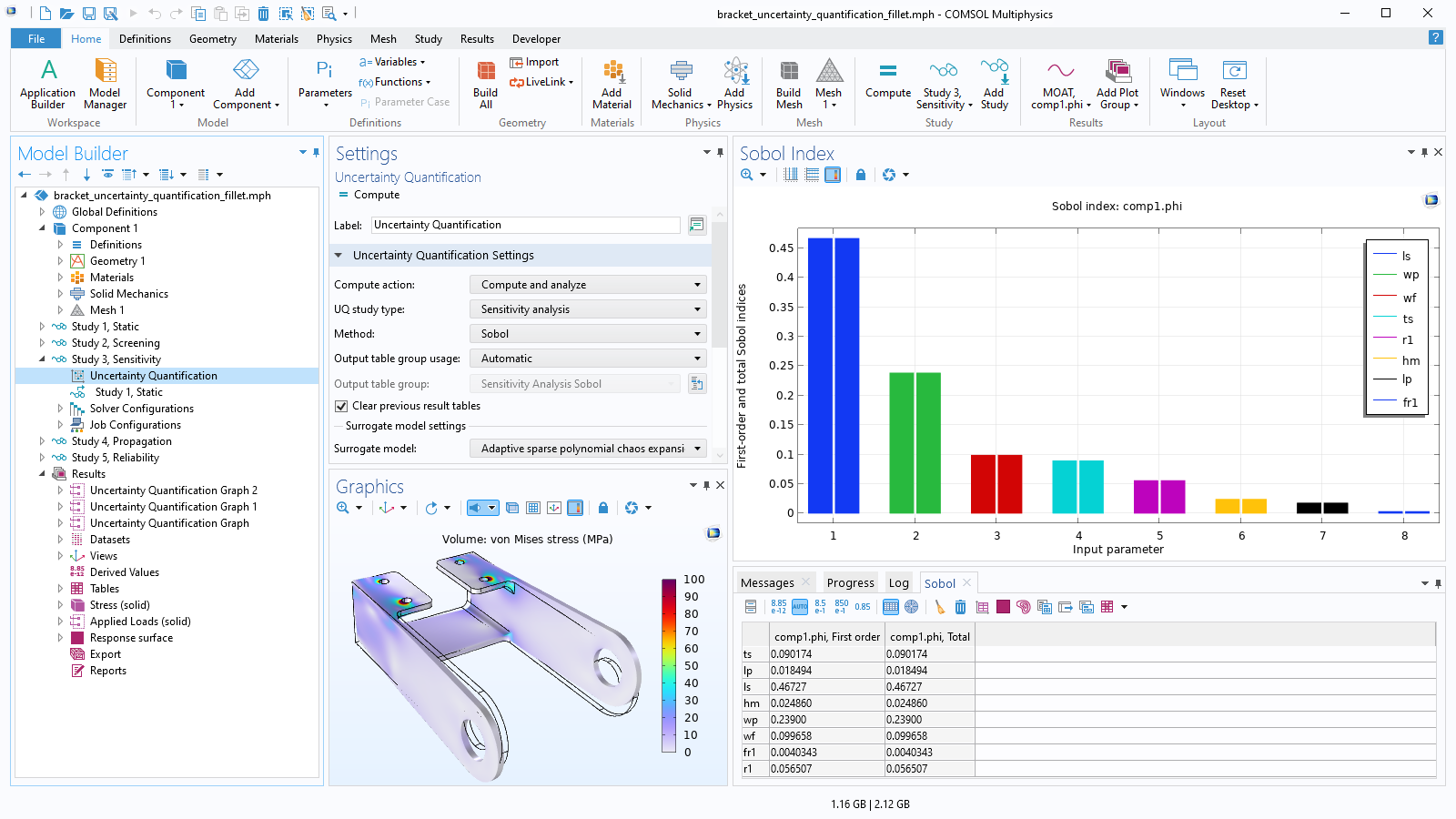

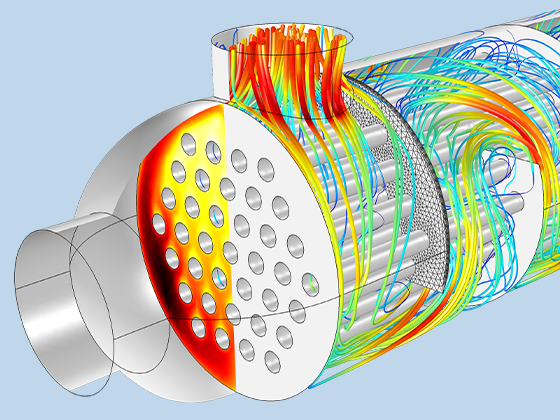

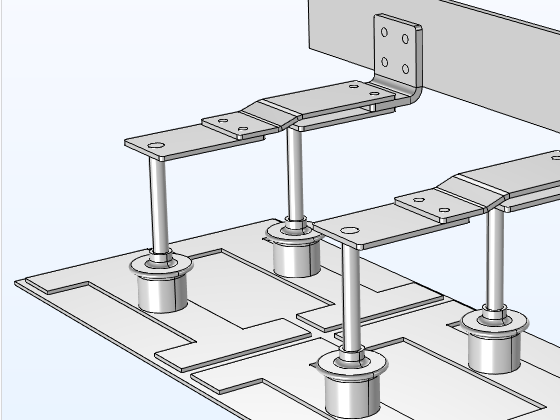

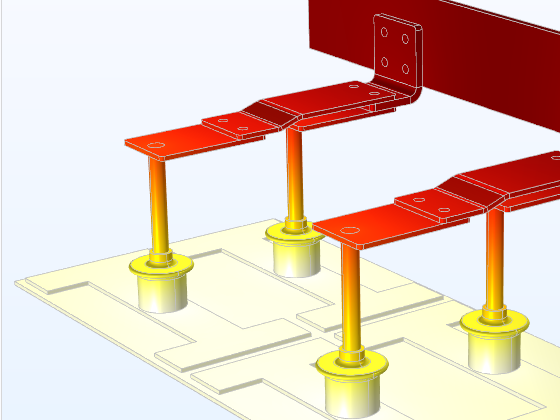

Modeling is useful together with experiments for optimizing processes and devices quicker and often more efficiently and accurately than running experimental methods or testing prototypes alone. By developing experimentally validated models for your analyses, you can gain a deeper understanding of the design or process because you can study it in a more convenient manner than in the lab.

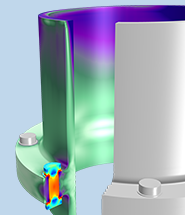

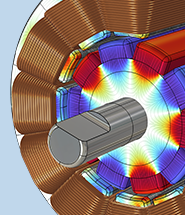

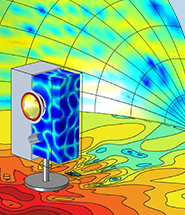

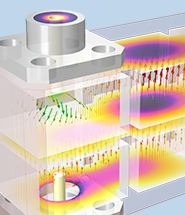

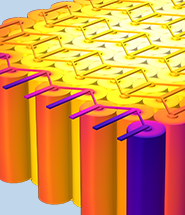

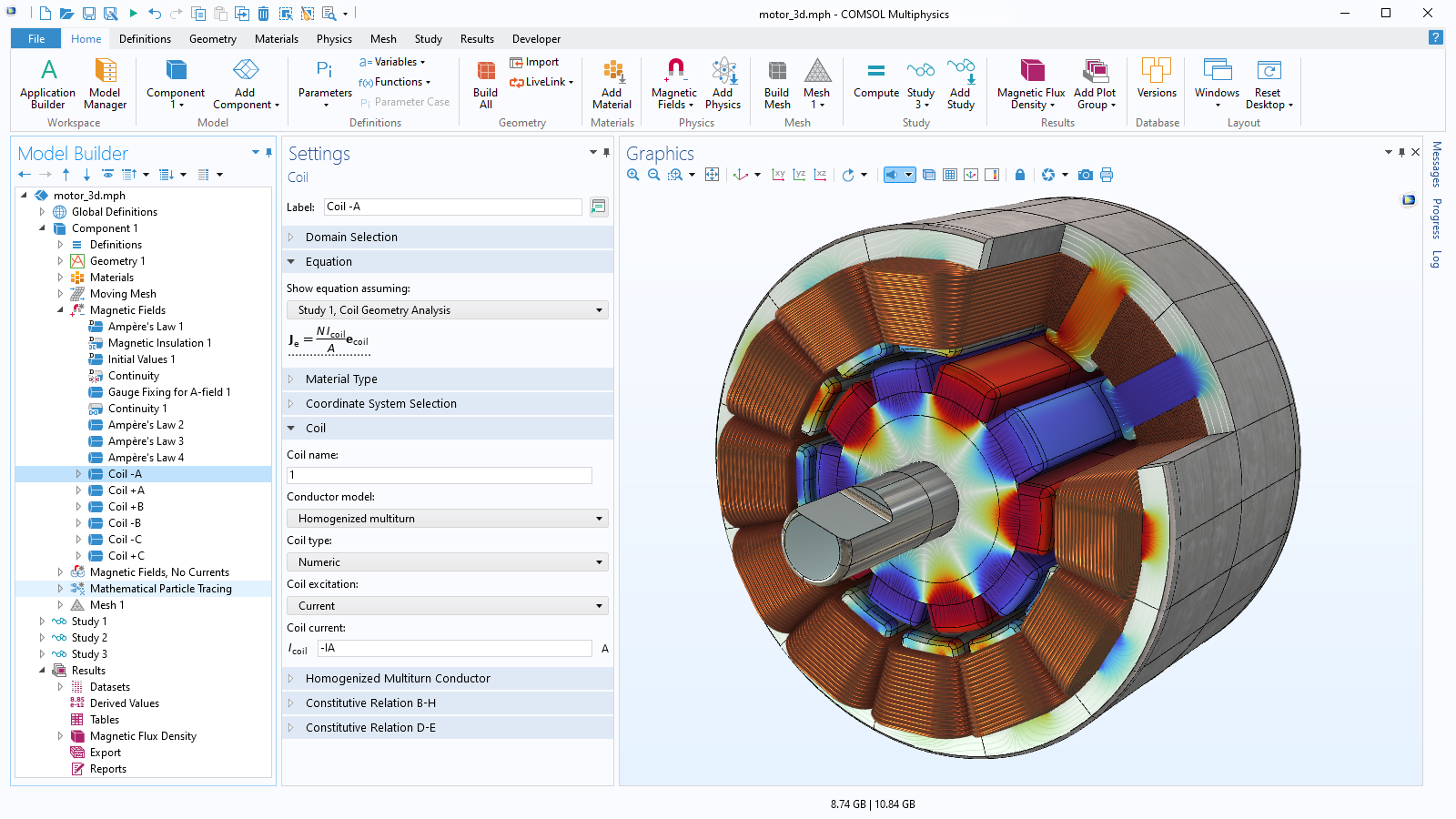

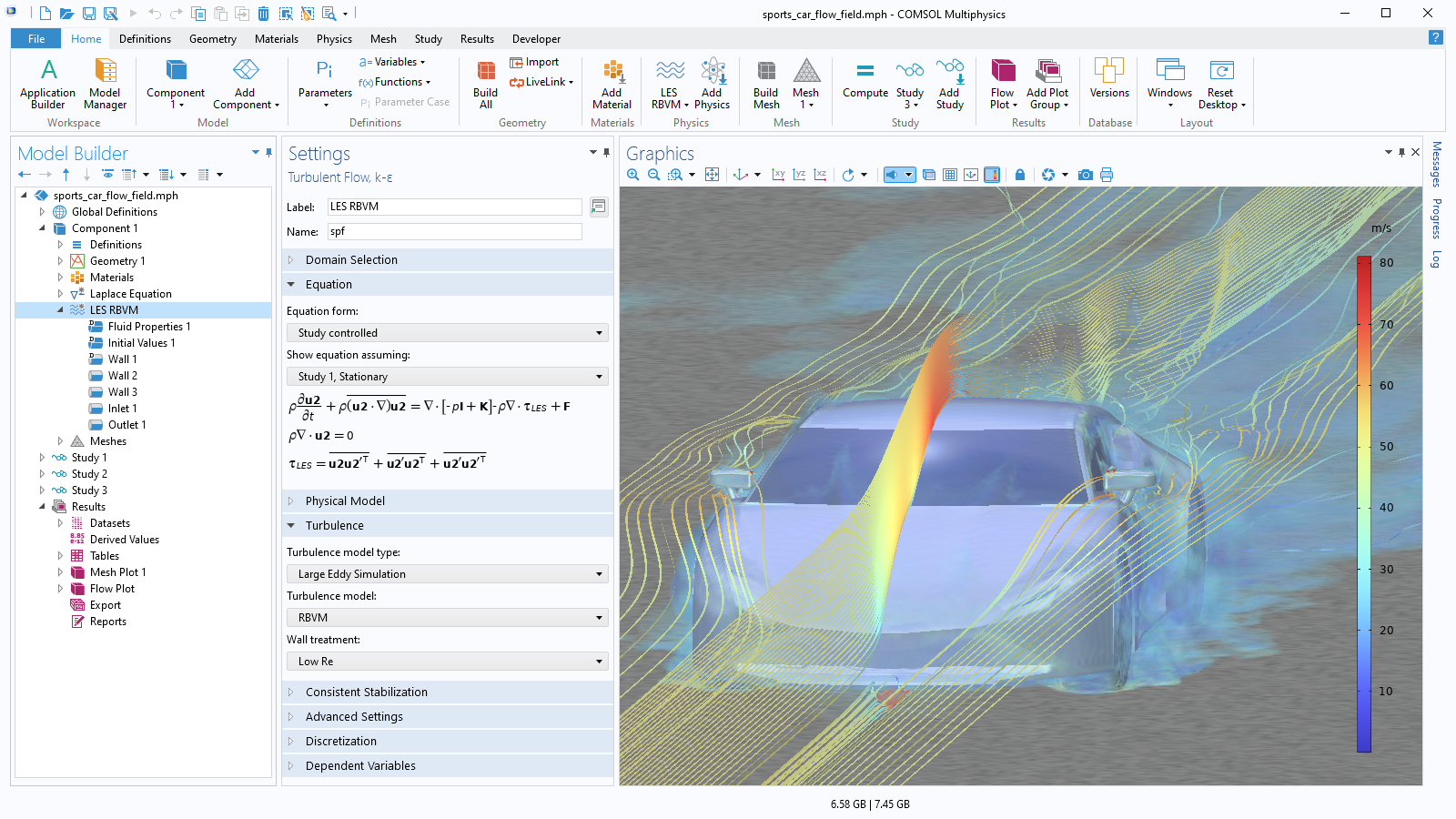

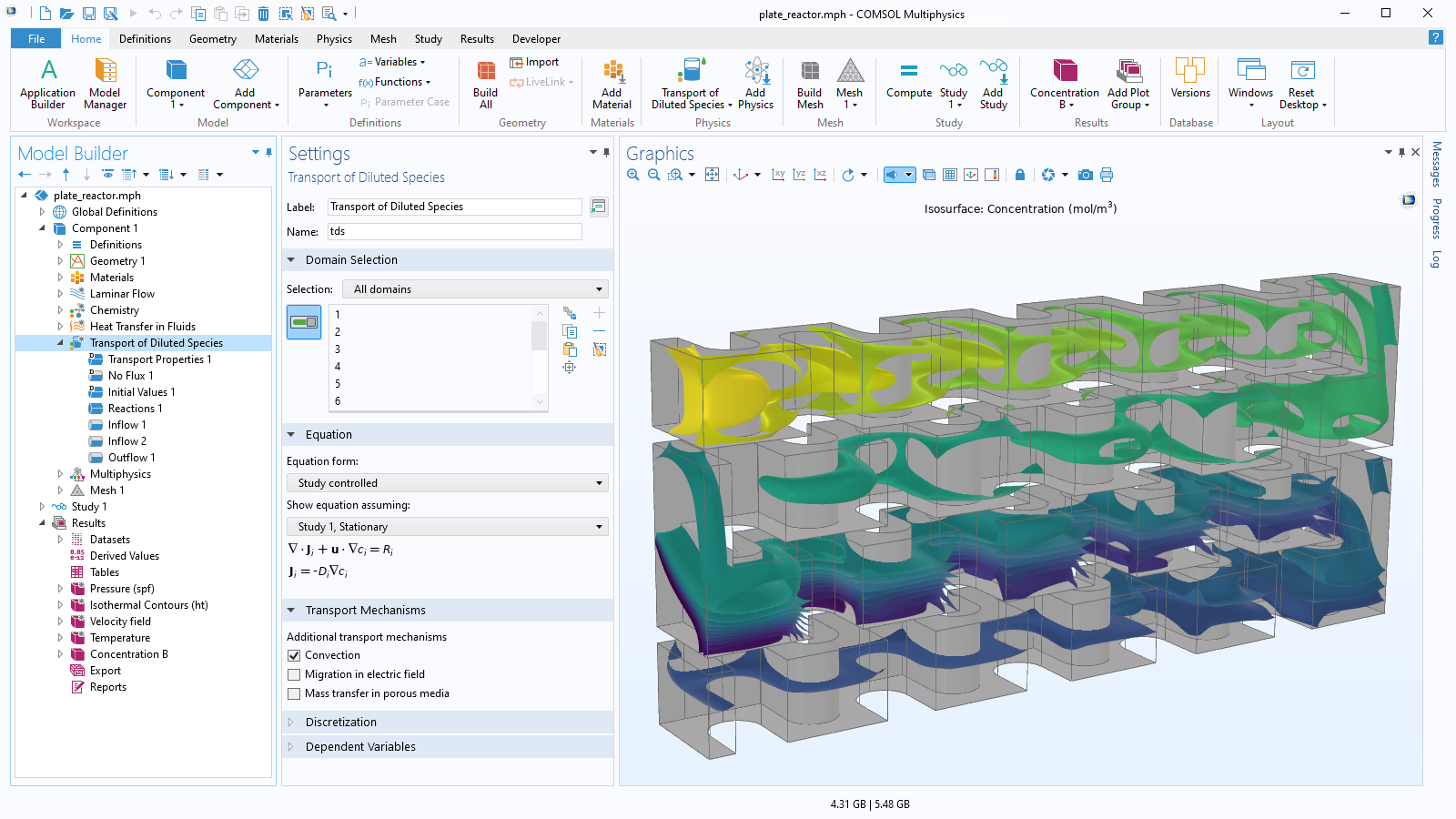

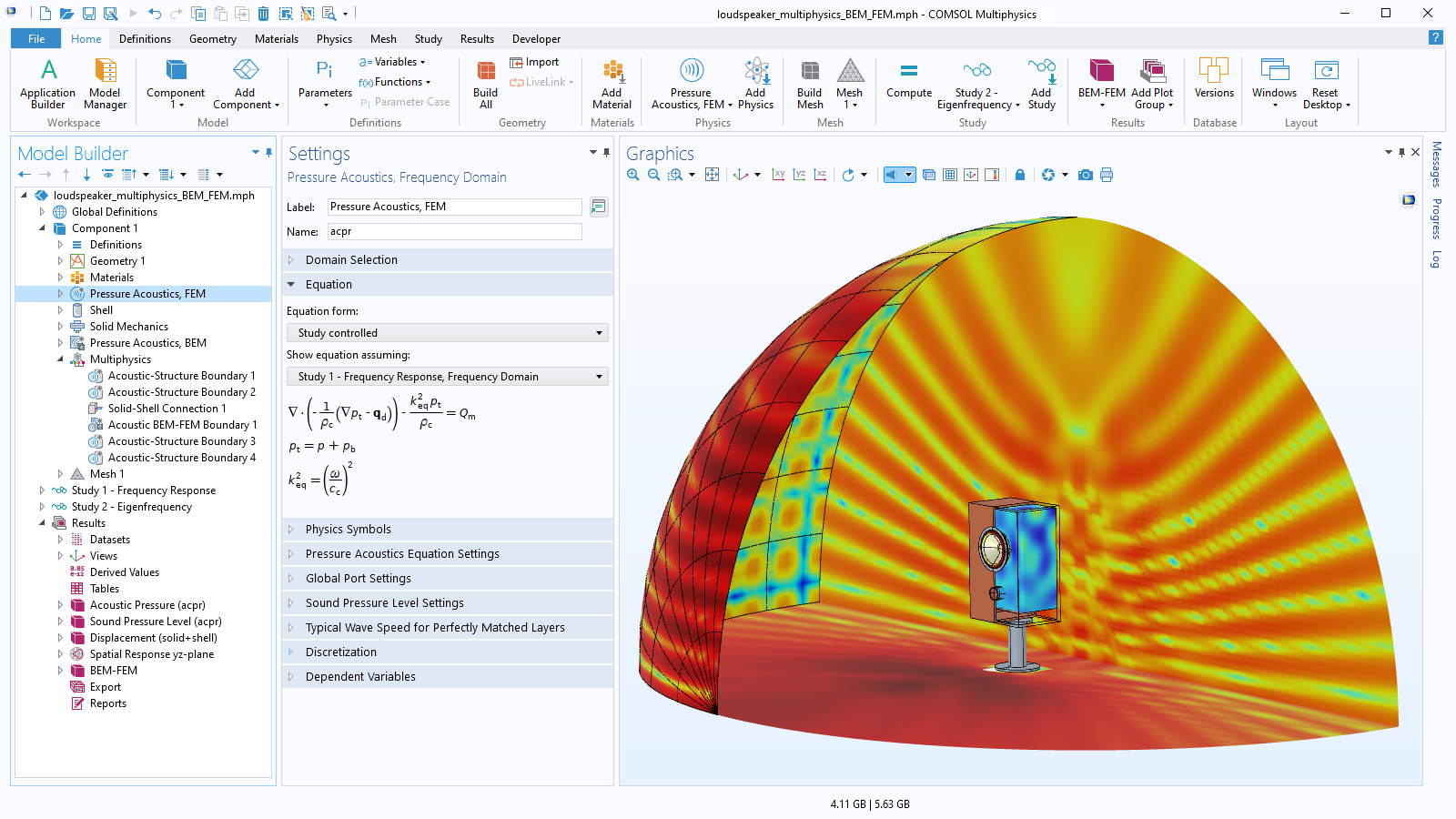

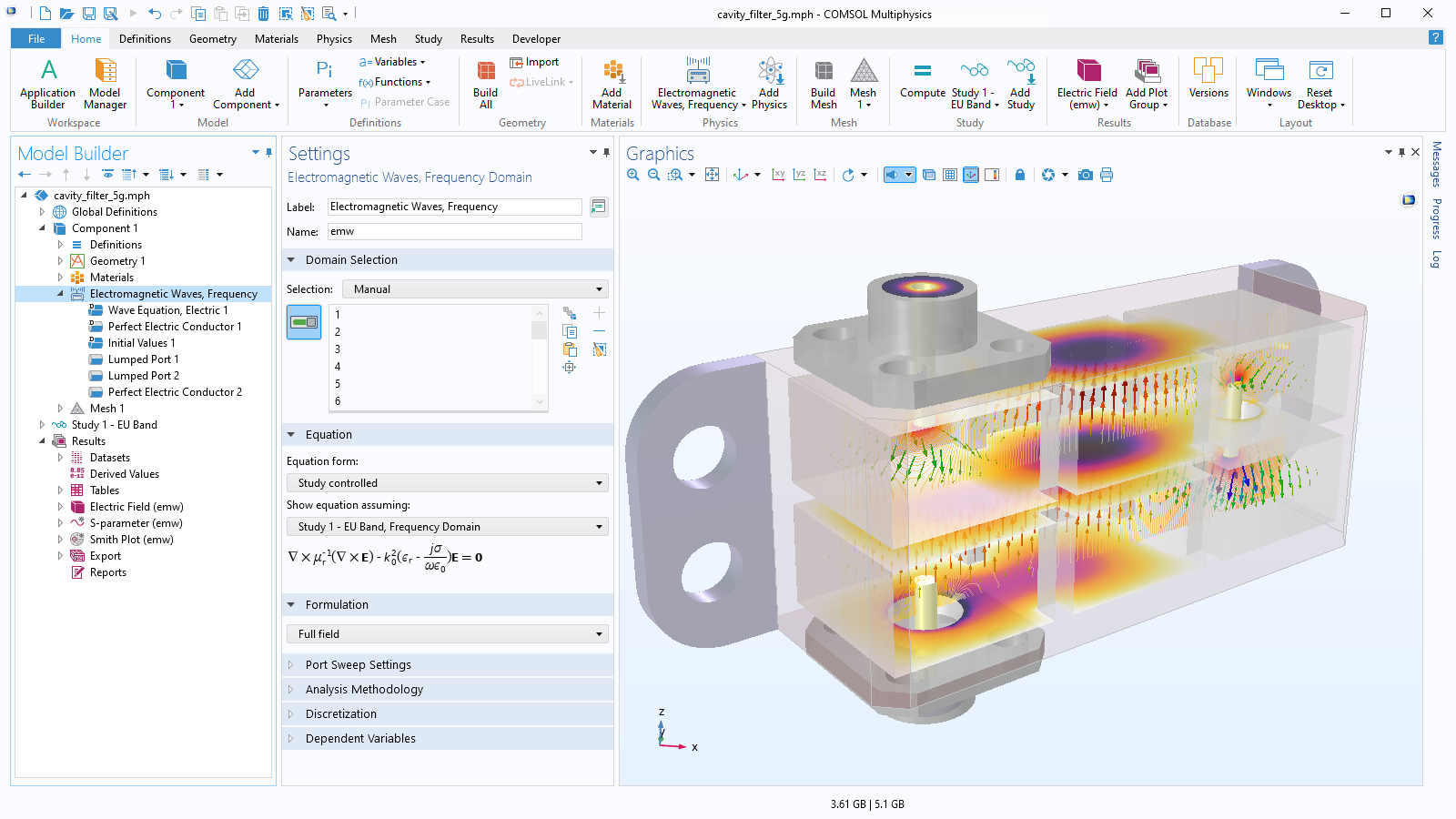

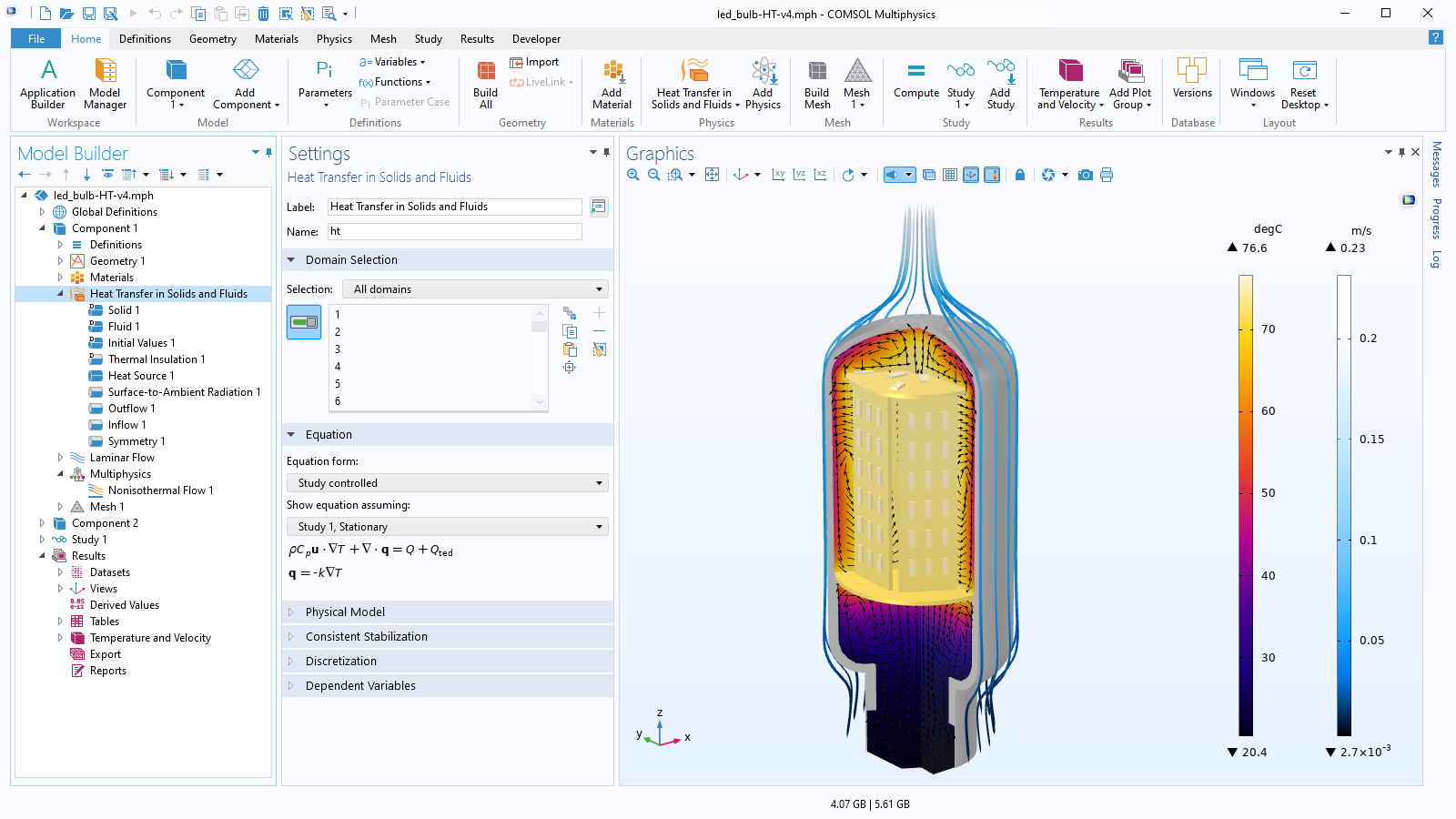

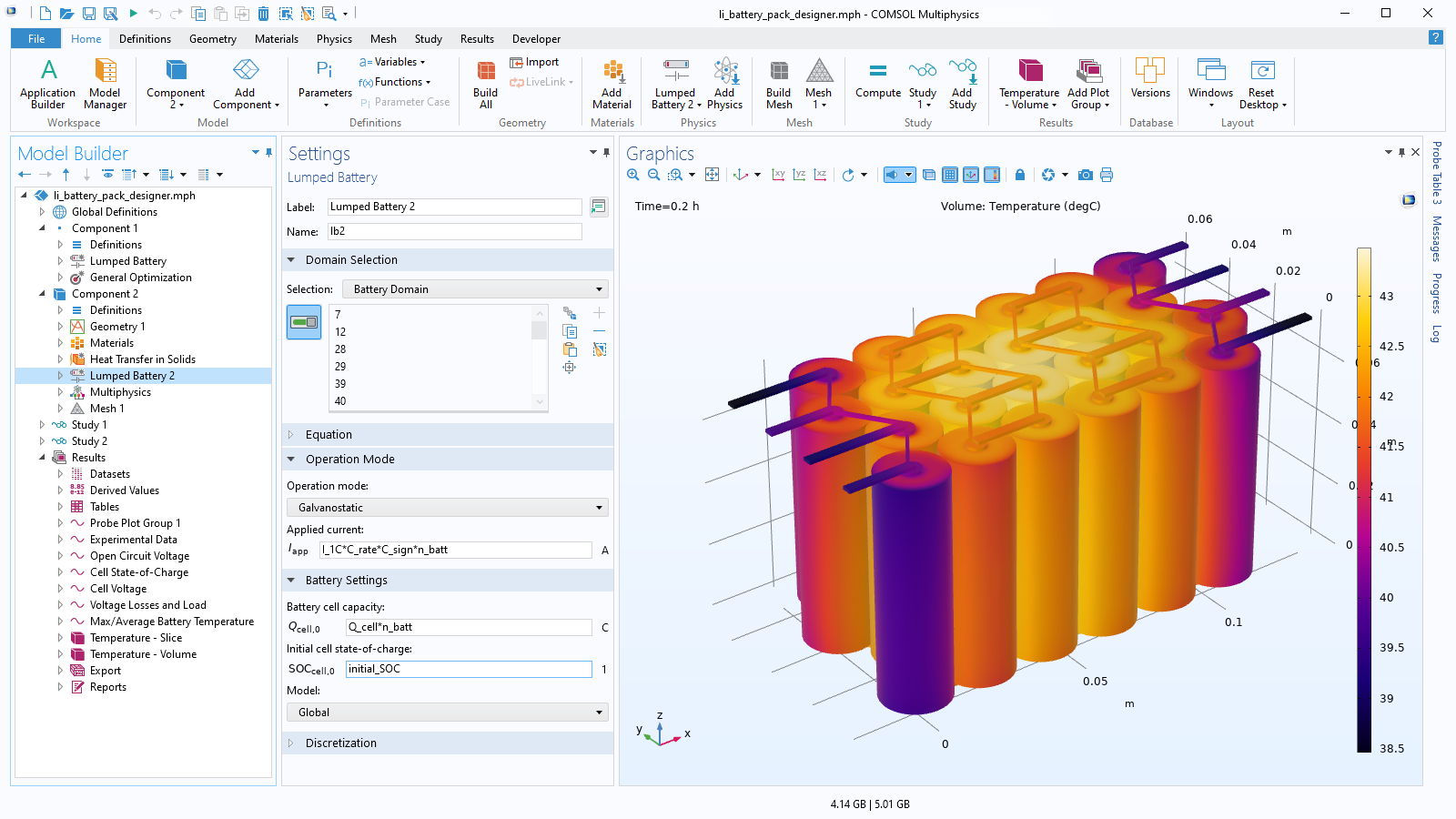

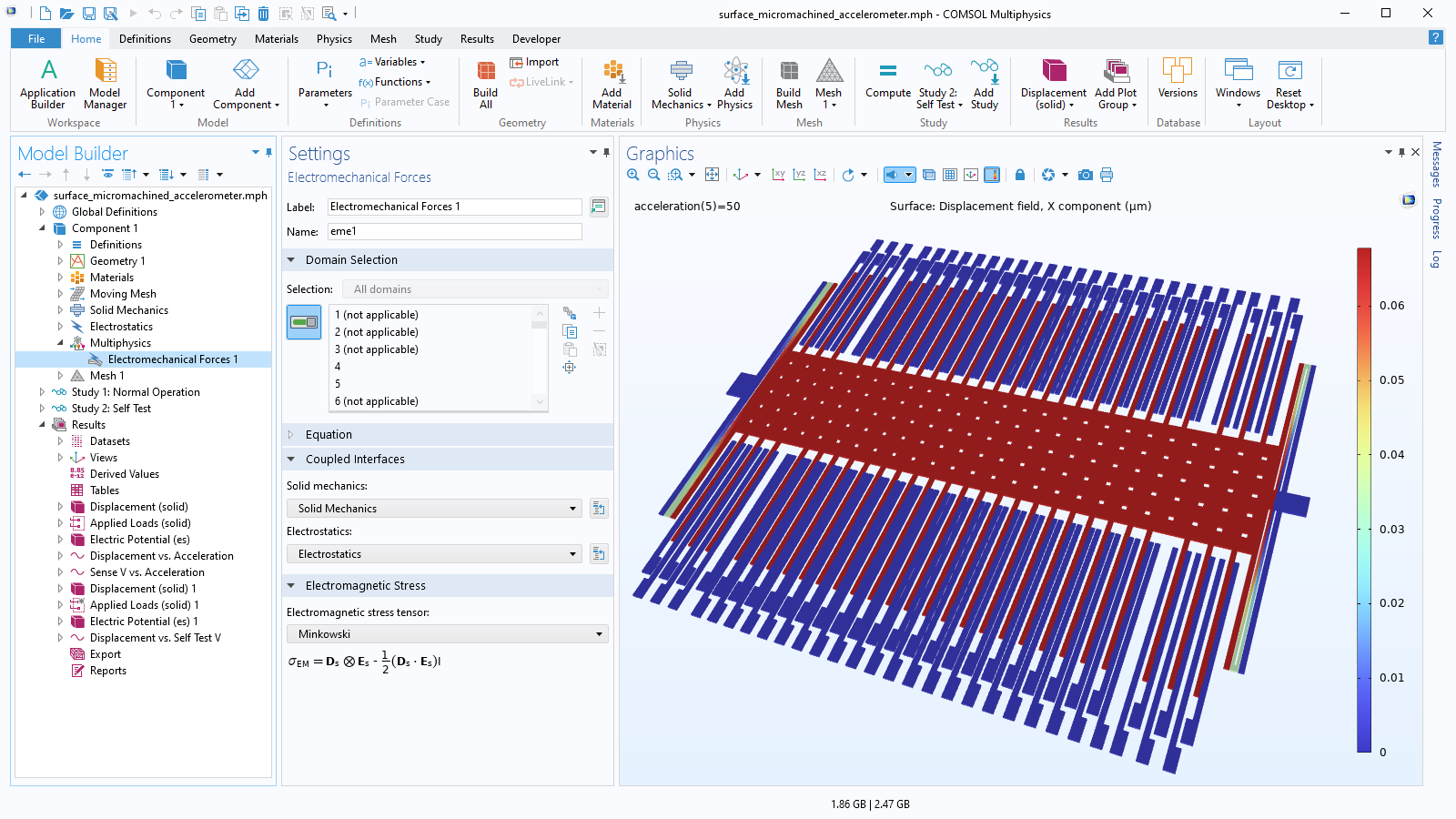

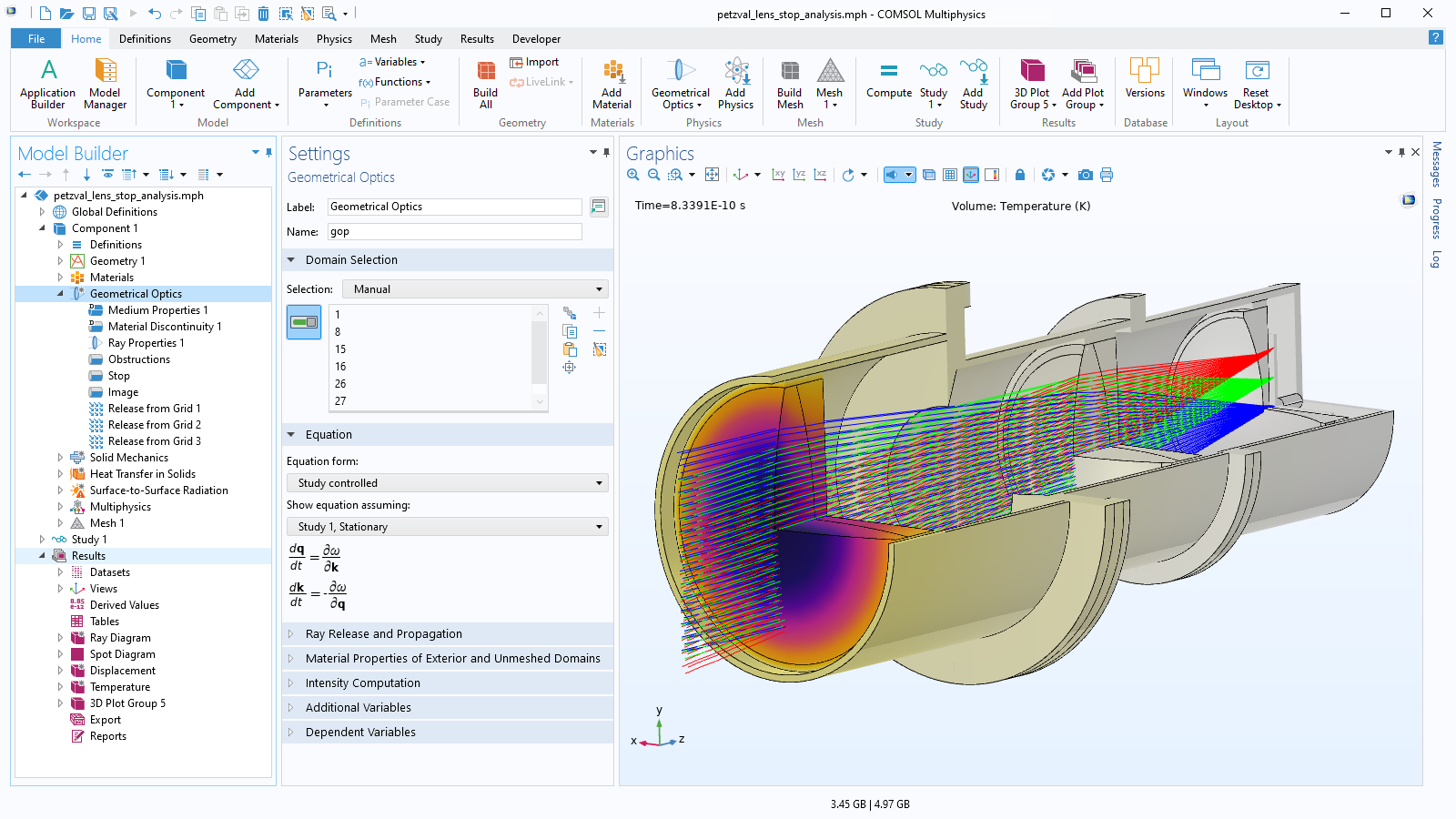

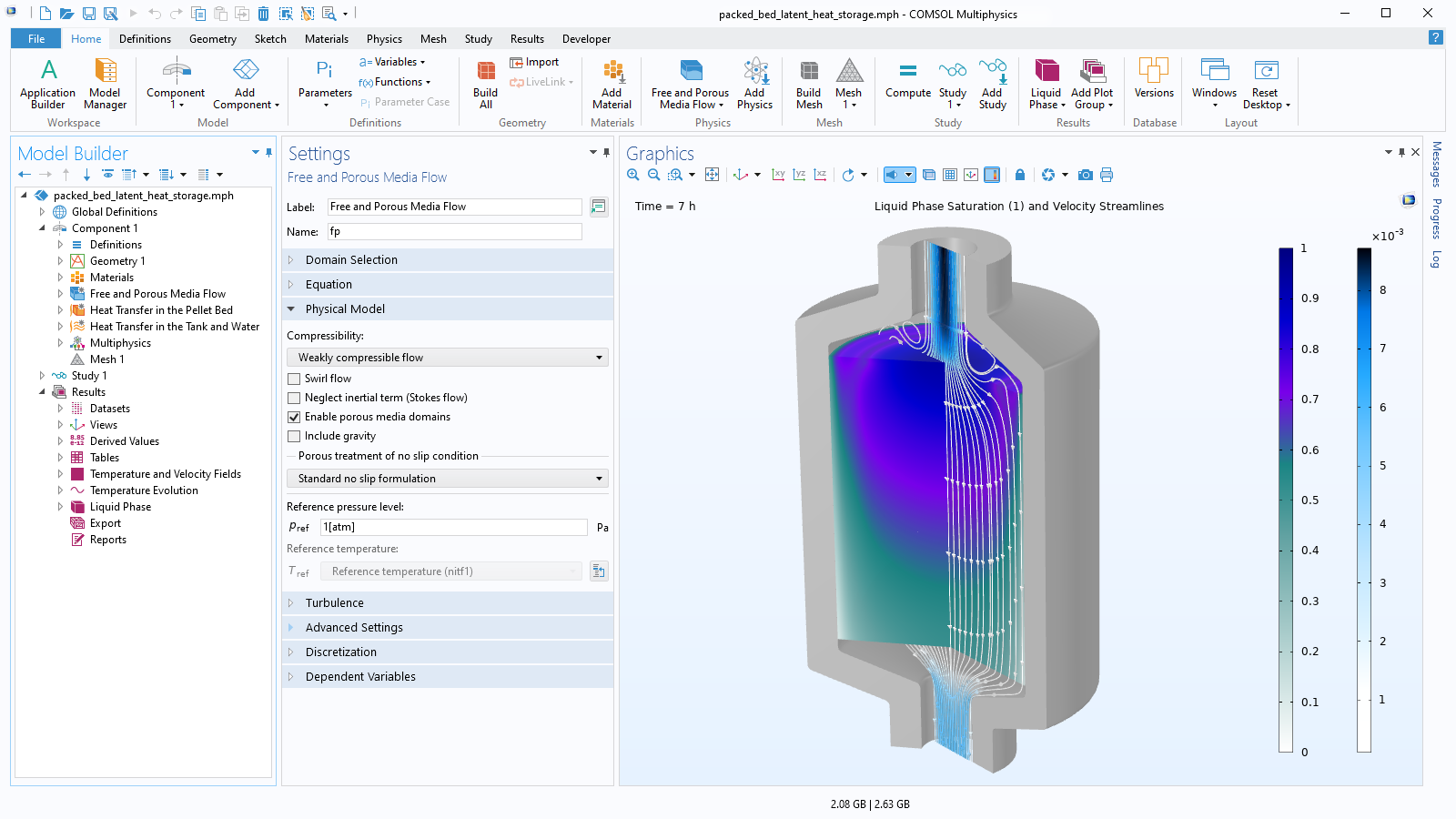

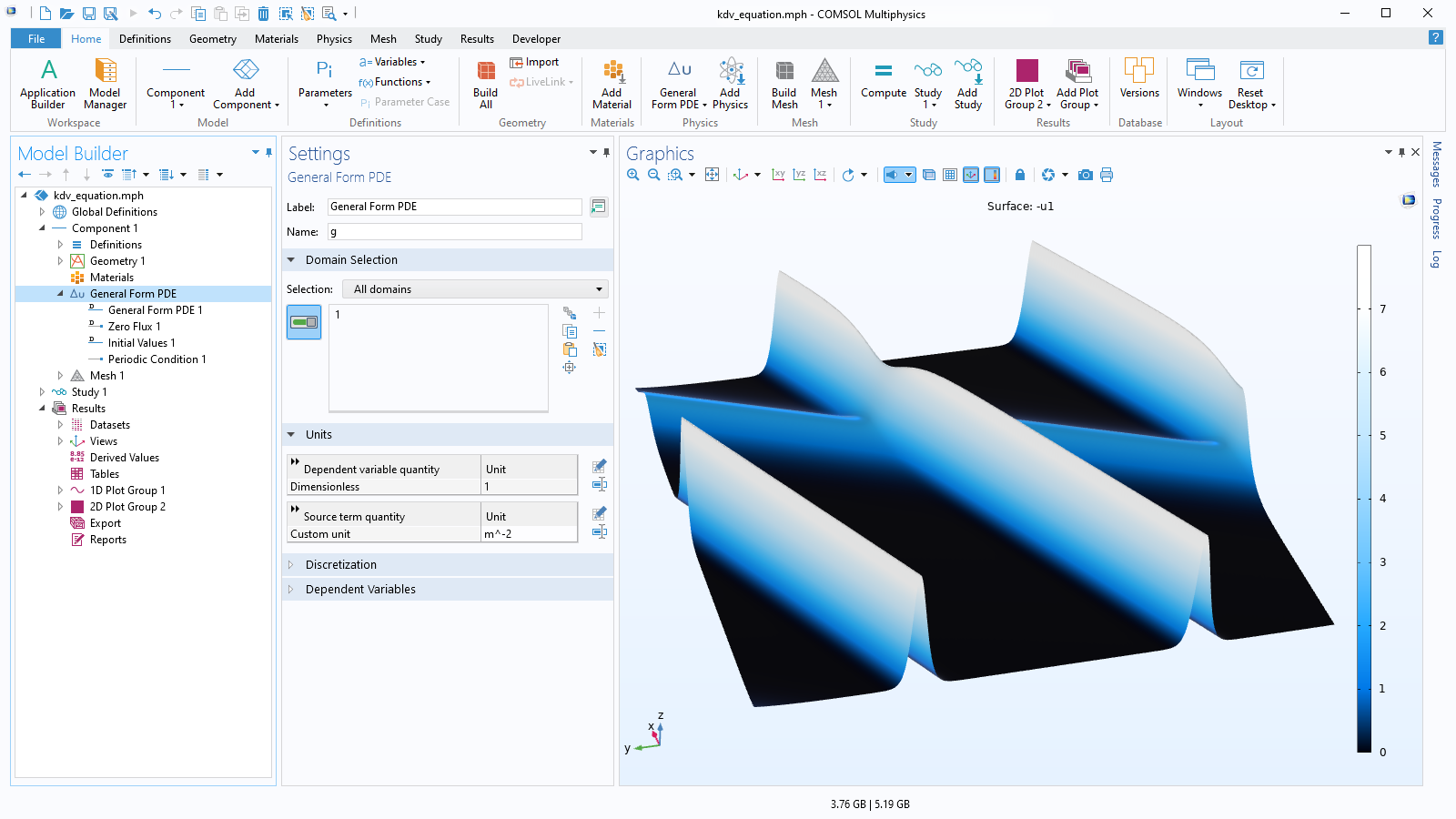

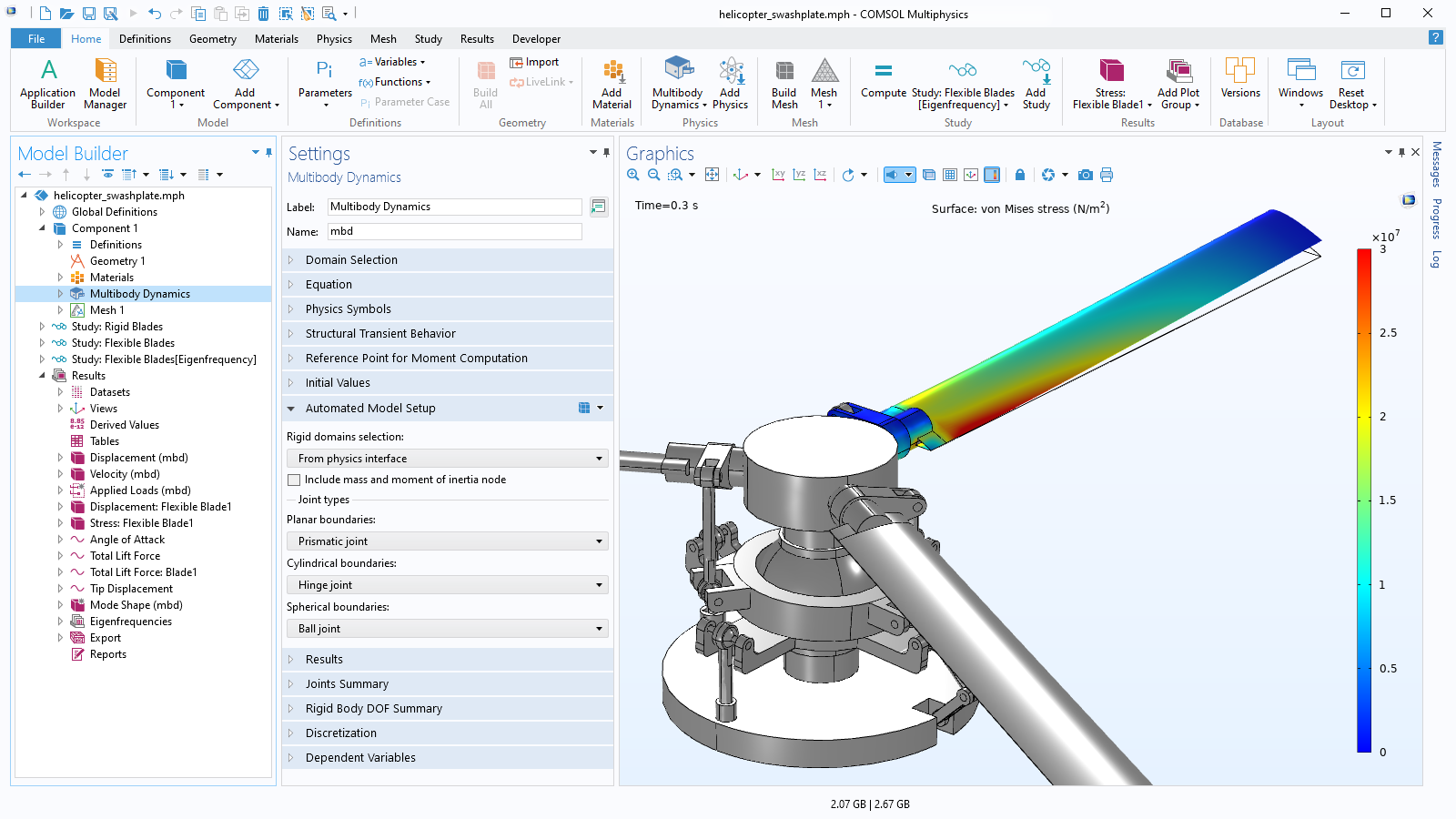

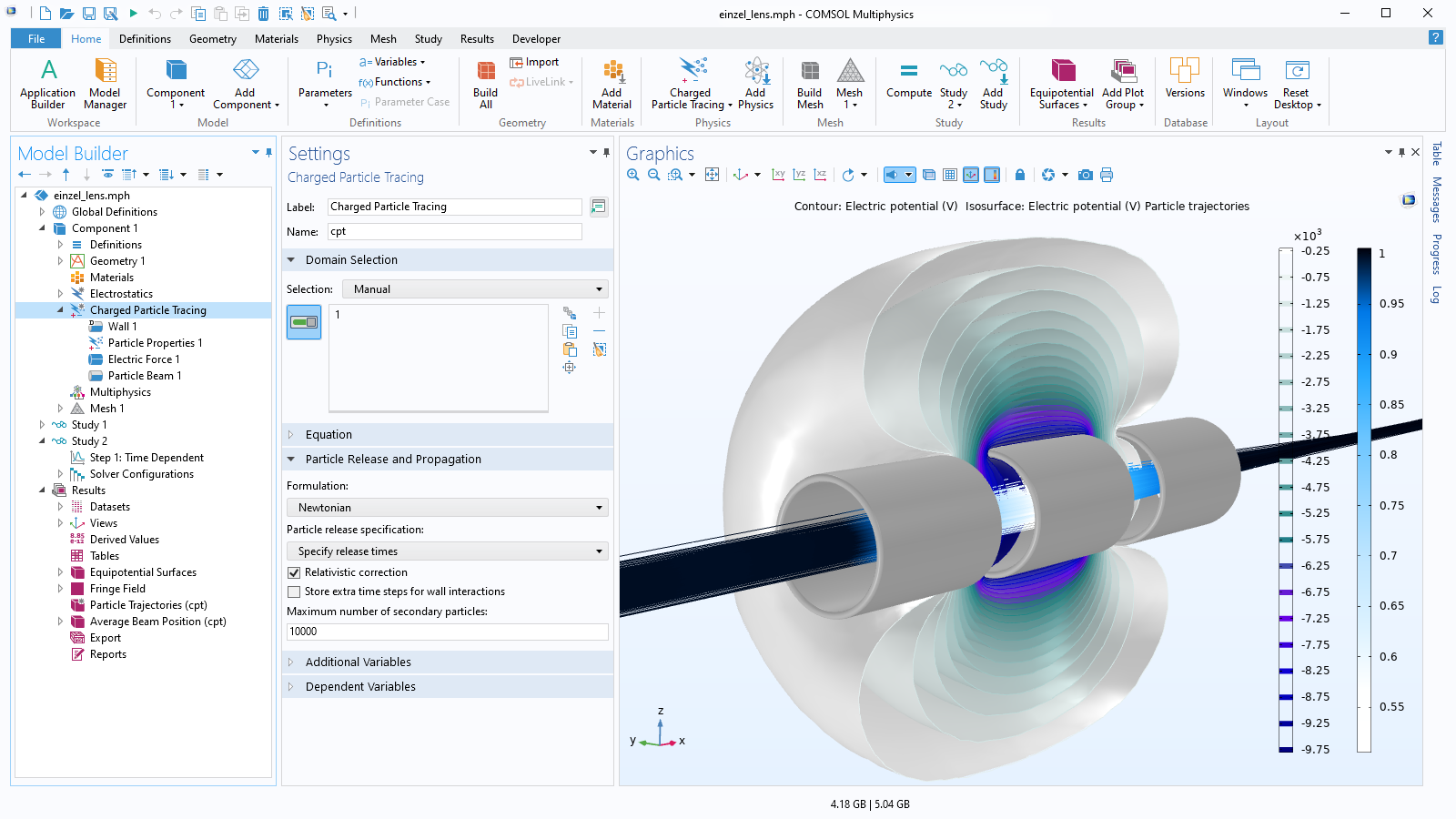

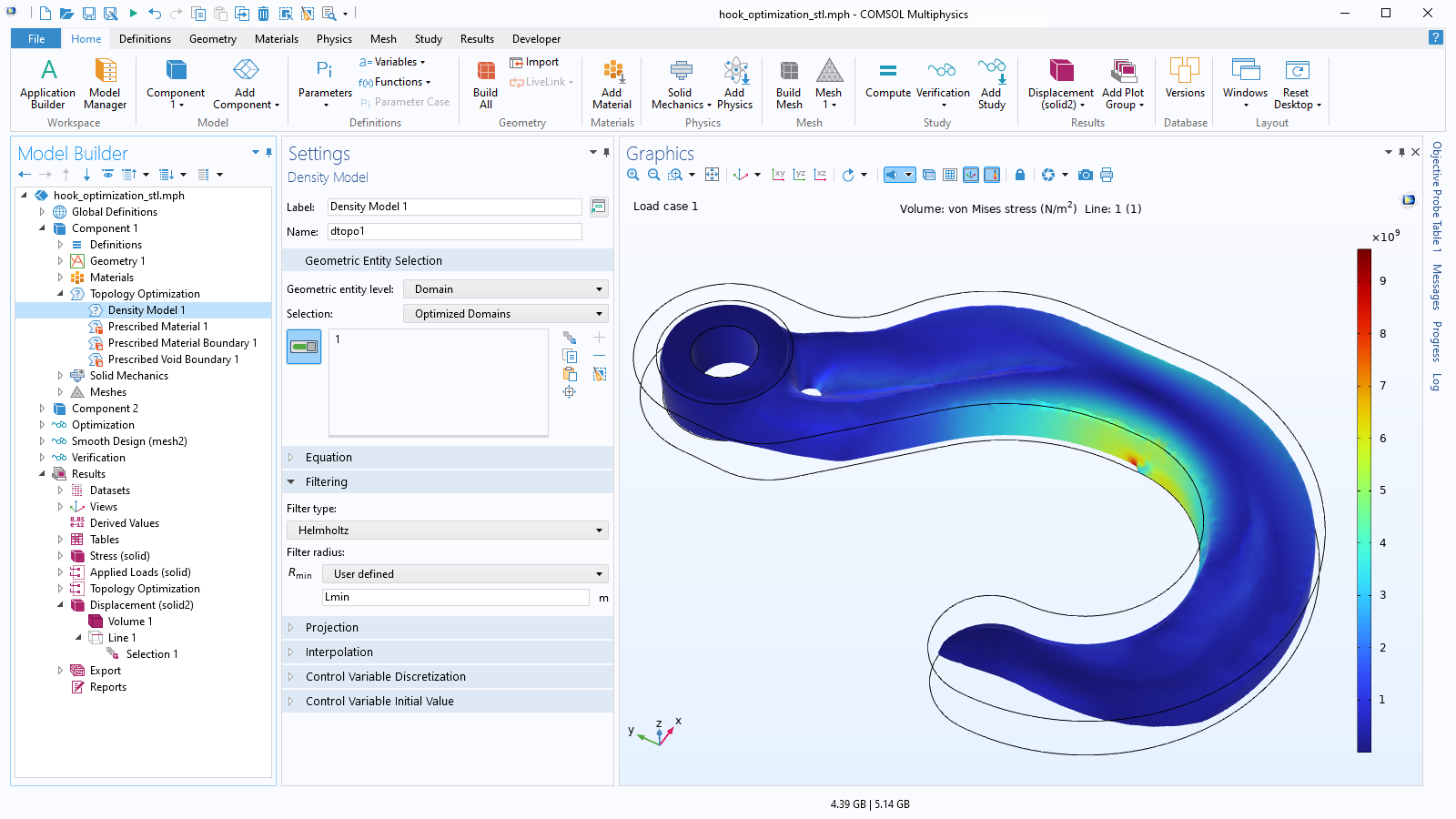

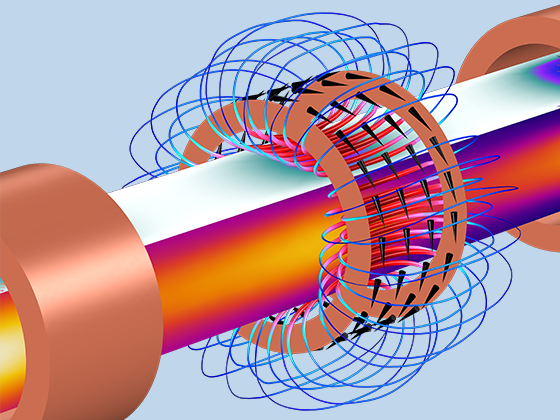

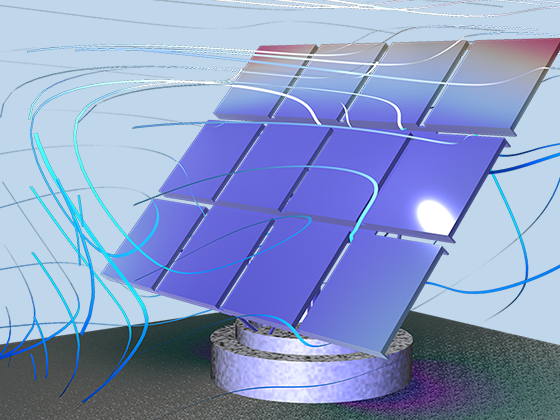

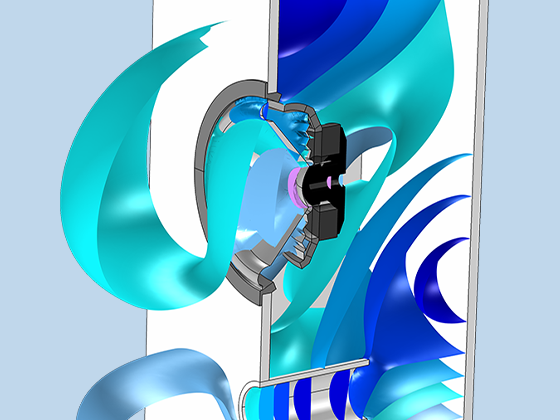

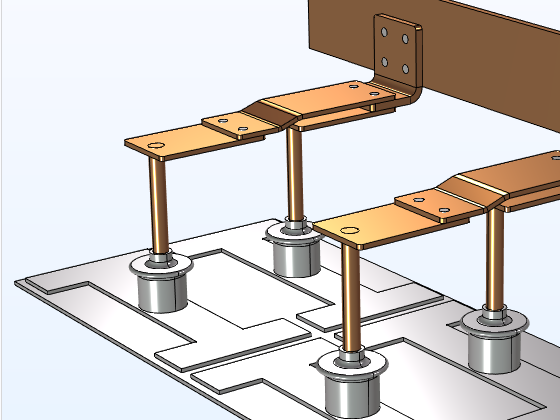

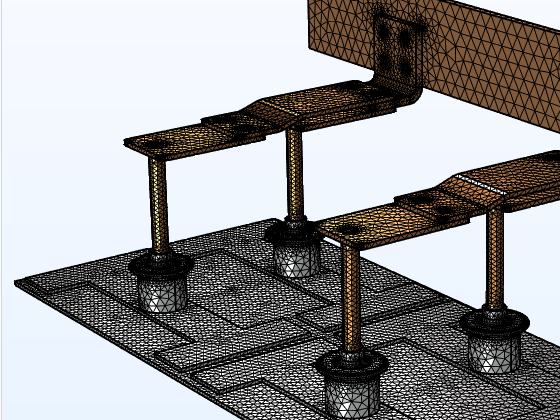

Multiphysics is often a necessity for accurately modeling your design or process. As a user of COMSOL Multiphysics®, you are free from the restrictive nature generally associated with simulation software and have complete control over all aspects of your model. You can be creative in a way that is impossible, or a lot harder, with traditional approaches, thanks to the ability to couple any number of physics phenomena together. For even further customization, input user-defined physics descriptions, with associated equations and expressions, directly in the user interface.

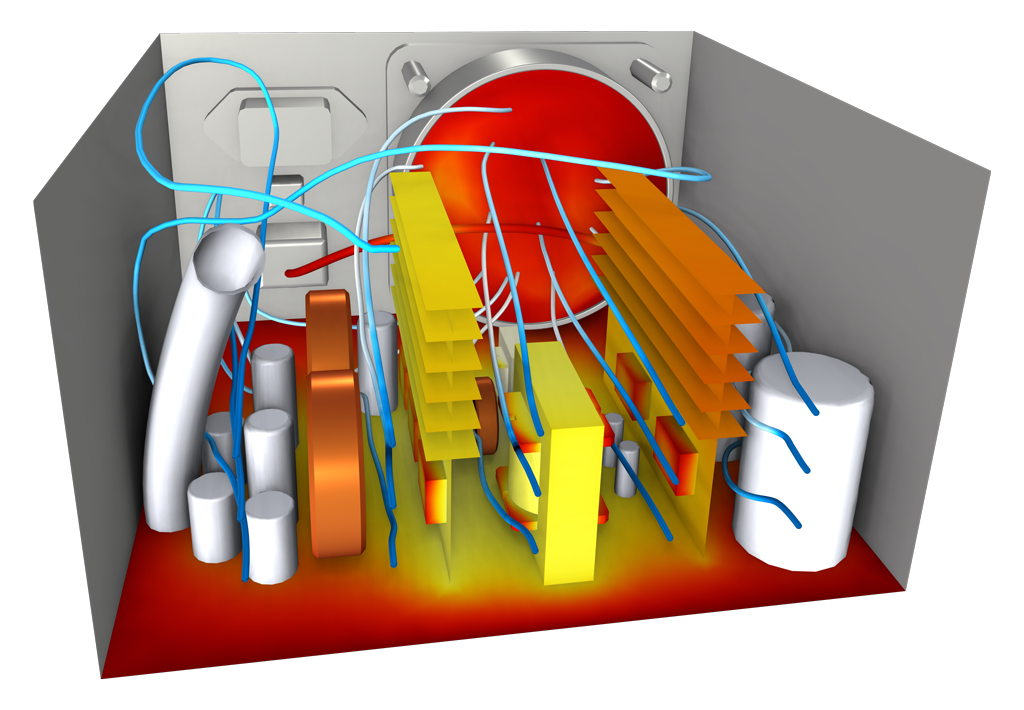

Accurate multiphysics models consider a wide range of possible operating conditions and physical effects. This makes it possible to use models for understanding, designing, and optimizing processes and devices for realistic operating conditions.